Unleash The Potential Of Blockchain For Supply Chain Management

My Geeks: A strong supply chain gets products and services to customers faster, which cuts costs for the company in the long run. Management of the supply chain has become an important part of any business. It can be anything that a business makes or sells. To keep customers happy and meet financial goals that could affect a company’s growth and size, it’s important to have a supply chain network that people can trust.

There are a lot of problems, and they vary by industry and market segment. Some industries, like automotive, FMCG, and retail, make products. Other industries, like retail, service at the end point, and distribution of products are also part of what they do. Even though cloud and ERP technologies do a good job of managing the complexity of supply chain activities, there are still problems with governance, communication, data management, and collaboration that blockchain could solve. Most importantly, there is no way for systems to talk to each other. Data silos and tech stacks make things even more complicated.

Let’s find out how Supply Chain Management works?

A supply chain is everything that happens between getting raw materials and making things. Supply chain management needs good systems and processes that make it easy to see how information flows, decisions are made, and goods and services are delivered. Their job is more than just coordinating logistics and buying stock. It also covers the overall operations of the supply chain to improve efficiency and cut costs. Good supply chain management keeps companies out of the news and keeps them from having to pay for expensive lawsuits and recalls.

Here are some high-level ways to put supply chain processes into groups. It can be different for each company.

Planning

The first step in supply chain management is to schedule and plan the activities that go into making goods and services, as well as organize and manage all the resources that are needed to meet customer demand for a product or service. To get the plan and goals across to the different departments, you need good metrics.

Sourcing

Companies that work on developing new products can see how complicated sourcing can be. Some of the most important things a supply chain sourcing does are buy, get, manage inventory, and approve payments to suppliers.

When the supply chain is spread out across the world and parts are made or bought in different places based on cost, availability of resources, or expertise, it makes things more complicated. The complexity also changes based on the number of batches and the total number of items made. Logistics and shipping are also affected by how big and complicated the product is ( Heavy parts, fragile parts, assembly of complex parts). The development of suppliers is another big problem. It requires space, equipment, knowledge, a chain of suppliers, a certain location, and a lot more. All of these things change how hard it is to communicate, keep track of inventory, exchange data, and manage data. First of all, communication and data exchange between departments can cause problems. Companies have gotten help from Cloud, PLM, PDM, SAP ERP, and digital solutions, but the problems are far from being solved.

Manufacturing

Today’s manufacturing engineering systems run things in a fair way and help all the different people involved communicate and share information so that the goods and services can be made and delivered. When data is exchanged with suppliers and support teams in different parts of the world, problems arise. Collaboration and communication between the R&D, production, sourcing, finance, purchase, and logistics teams inside the company are often disorganized and take a long time. Communication is made more difficult by suppliers and vendors. Auditing the process and making sure that the exchange of data can be traced back to historical information is often difficult. Layers of disconnected communication happen upstream and downstream because of different technology stacks. This causes chaos and a lot of things that don’t add value, like overprocessing, unwanted motion, defects, and waiting time. Any company could manage the supply chain well if there was a governance layer on top of communication and collaboration that was linked to business metrics and customer metrics. This is how a reliable blockchain development company helps both big and small businesses. Blockchain brings together all the parties involved, automates tasks, notifications, and metrics, and makes governance more effective. It works with all kinds of technology to make systems work together. It makes it easier to keep track of data and keep it safe all along the supply chain. This makes it a useful tool for governance.

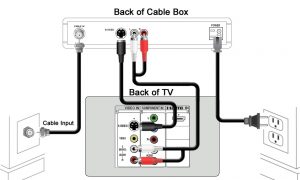

Your connection is not private, for the issue, you can fix it, at your end. If you are reading this information and facing the same problem again and again, then this video is for you.

Shipping and Logistics

Logistics and transportation costs are getting worse because of government policies and rules, problems with warehouses and distribution, and the inefficiency of road, rail, water, and air transportation. Companies have realized that they need a full technology stack that includes Telematics, communications systems, and 5G internet to change the future of logistics. But a layer of IoT-enabled blockchain can help the hub-and-spoke model work better by making it easier to govern, share information, and talk to each other.

Accounting

This is the most important part of every financial deal. Accounting keeps track of the costs and expenses of each process when all the products have been delivered. It also makes sure that rules are followed and gives supply chain managers real-time information about how the whole system is doing.

Human Resource

Management of human resources is an important part of management of the supply chain. It means allocating resources (both contract and full-time), making sure payrolls are done on time, keeping track of performance, and working closely with leaders and managers to reach the desired metrics. HR tech is used for communication between HR leaders, managers, and partners, just like Fintech is used for finance. All of these different technologies make it harder to communicate, measure, and share data, which hurts the supply chain’s productivity and efficiency. Smart contracts on the blockchain are a good way to bridge these gaps.

Retail/Pre-sales

Aftermarket and retail are usually their own big oceans that aren’t connected to the rest of the supply chain. They have their own needs for technology and processes. In the automotive industry, data silos are a problem. Aftermarket retail and service centers have their own ways of running things that aren’t connected to the rest of the supply chain. This makes things less efficient.

How is Blockchain Development suited for Supply Chain Management?

Data, services, and communication are all handled separately in modern supply chains. Modern systems for managing the supply chain are set up to work well, but they aren’t quite there yet. The missing link is the way systems are run. When blockchain is used in supply chain management, it leads to better products and services, on-time delivery, lower costs, a more interesting customer experience, and more money in the bank.

Effective integration of blockchain can add value to the supply chain cycle by:

Trying to predict delivery problems and stock shortages

When the number of orders for a product is more than what the company can make or deliver, the buyer can worry about bad service or late delivery. Integrations of IoT blockchain make it possible for stakeholders to analyze data, make predictions, and set up governance modules ahead of time. This lets supply chain managers know about shortages of deliverables before the buyer feels let down.

Adjusting prices in real time

Most of what is made are seasonal items that can only be kept for a short time. After their seasons are over, these items are no longer useful. At the end of the season, they are usually thrown away or sold for less money. Many businesses, like airlines and hotels, change the prices of “products” that go bad quickly to keep up with the market. This problem can be solved with a layer of analytical tools on top of the blockchain. This will help predict and reduce surprises while making sure that goods and services are delivered on time.

Adding more redundancy to inventory and delivery

Blockchain lets supply chain managers assign resources on the fly and plan manufacturing and other processes based on actual orders, sales forecasts, and when raw materials are supposed to be delivered. Manufacturers can guarantee a fixed delivery date for a product when the order is placed because they have access to all the logistics and inventory data at the same time. This makes it much less likely that a request was made in error.

Linked to everything

Blockchain can easily access unstructured data from social media, structured data from Internet of Things (IoT) devices, and more traditional data sets without limits through ERP and B2B integration. It can also use GPS and other sensors to confirm when products are shipped and when they are delivered.

Ecosystems that work together

By sharing data, blockchain makes it easier for suppliers and other middlemen to work together. It connects to cloud-based commerce portals, which are becoming more and more popular, so that businesses can work together and engage with each other to improve how they deliver products and services to their customers.

Cyber-aware

Users can access encrypted data that is only available to other members of the same network. It makes the systems in the supply chain stronger and protects them from cyber fraud and hacking, which is a concern for the whole business.

New technology that helps people think better

AI platforms can also be used with the blockchain to help the modern supply chain collect, coordinate, and make decisions and take actions all along the chain. Most of the tasks in the supply chain are taken care of by machines that learn on their own.

Final Takeaways

40% of supply chain supervisors said it was hard to share data and make sure it was correct throughout their supply chain, and the problems have never been worse. When there are problems in the supply chain, costs go up and, more importantly, revenue goes down. These problems are made worse by inefficient processes that don’t use trusted or up-to-date data.

Businesses want their supply chains to be open, strong, and flexible so they can handle things like lockdowns and slowing economies. As a part of your supply chain technology, blockchain forces everyone involved to trust, be clear, and agree. It gets the most out of flexible business outcomes while helping everyone involved.

With real-time data, blockchain analytics can be made better and better. The speed and depth of insights improve. As soon as blockchain participants can connect to each other’s data, latency is reduced or goes away completely.

Read More:

1 thought on “Unleash The Potential Of Blockchain For Supply Chain Management”

Comments are closed.